Demand forecasting is modular and easy to configure. You can

turn the functionality on and off by changing the configuration key at Trade > Inventory forecast > Demand forecasting.

Demand forecast

variant conversion limitation

Unit of measure (UOM) per variant conversion is not

fully supported when generating demand forecast if inventory UOM is different

than the demand forecast UOM.

Generating forecast (Inventory UOM > Demand

forecast UOM) uses product UOM conversion. When loading historical data for

the demand forecast generation, the product level UOM conversion will be always

used when converting from inventory UOM to the demand forecast UOM, even if

there are conversions defined on the variant level.

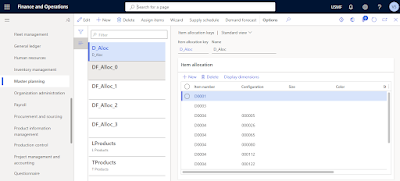

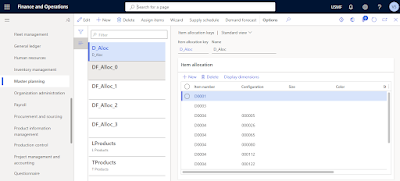

Item allocation keys

Item

allocation keys establish groups of items. A demand forecast is calculated for

an item and its dimensions only if the item is part of an item allocation

key.

An item and its dimensions must be part of only one

item allocation key if the item allocation key is used during forecast

creation.

To create item allocation keys and add a

stock keeping unit (SKU) to them, follow these steps.

1. Go to Master

planning > Setup > Demand forecasting > Item allocation keys.

2. Either select an

item allocation key in the list pane, or select New on the

Action Pane to create a new one. On the header for the new or selected key, set

the following fields:

·

Item allocation key – Enter a

unique name for the key.

·

Name – Enter a descriptive name for

the key.

3. Follow one of these

steps to add items to the selected item allocation key or remove item

On the Item allocation FastTab, use the New and Delete buttons on the toolbar to add or remove items as needed. For each row, select the item number, and then assign dimension values in the other columns as you require. Select Display dimensions on the toolbar to change the set of dimension columns that is shown in the grid. (The value in the Percent column is ignored when demand forecasts are generated.)

If you want to add a large number of items to the key, select Assign items on the Action Pane to open a page where you can find and assign multiple items to the selected key.

Set up Demand forecasting parameters

Use

the Demand forecasting parameters page

to set up several options that control how demand forecasting will work in your

system.

Open the Demand forecasting parameters page

To

set up demand forecasting parameters, go to Master

planning > Setup > Demand forecasting > Demand forecasting parameters.

Because demand forecasting runs cross-company, the setup is global. In other

words, it applies to all legal entities (companies).

General settings

Use

the General tab of

the Demand forecasting parameters page

to define general settings for demand forecasting.

Demand forecast unit

Demand

forecasting generates the forecast in quantities. Therefore, the unit of

measure that the quantity should be expressed in must be specified in the Demand forecast unit field. This

field defines the unit that will be used for all demand forecasts, regardless

of the usual inventory units for each product. By using a consistent forecast

unit, you help ensure that the aggregation and percentage distribution make

sense.

Transaction types

Use

the fields on the Transaction types FastTab

to select the transaction types that are used when the statistical baseline

forecast is generated.

Demand

forecasting can be used to forecast both dependent demand and independent

demand.

For example, if only the Sales

order option is set to Yes,

and all the items that are considered for demand forecasting are items that are

sold, the system calculates independent demand.

However, critical subcomponents can be added to item allocation

keys and included in demand forecasting. In this case, if the Production line option is set to Yes, a dependent forecast is calculated.

You

can override transaction types for one or more specific item allocation keys by

using the Item allocation keys tab.

That tab provides similar fields.

Override default forecast algorithm parameters globally

Default

forecast algorithm parameters and values are assigned on the Demand forecasting parameters page (Master Planning > Setup > Demand forecasting >

Demand forecasting parameters).

However, you can override them

globally by using the Forecast algorithm parameters FastTab

on the General tab of

the Demand forecasting parameters page.

(You can also override them for specific allocation keys by using the Item allocation keys tab on the Demand forecasting parameters page.)

Use

the Add and Remove buttons on the toolbar to

establish the required collection of parameter overrides.

For each parameter in

the list, select a value in the Name field,

and then enter an appropriate value in the Value field.

All parameters that aren't listed here will take their values from the settings

on the Demand forecasting parameters page.

Set forecast dimensions

A

forecast dimension indicates the level of detail that the forecast is defined

for. Company, site, and item allocation key are required forecast dimensions.

You can also generate forecasts at the warehouse, inventory status, customer

group, customer account, country/region, state, and/or item level, and at all

item dimension levels. Use the Forecast

dimensions tab on the Demand

forecasting parameters page to select the set of forecast

dimensions that is used when the demand forecast is generated.

At

any time, you can add forecast dimensions to the list of dimensions that are

used for demand forecasting. You can also remove forecast dimensions from the

list. However, manual adjustments are lost if you add or remove a forecast

dimension.

Generate a statistical baseline forecast

When you create a baseline forecast, you must first specify the

parameters and filters that are used in the calculation.

For example, you can create a baseline forecast that estimates

demand based on transaction data from the past year for a specific company, for

the coming month, and for a selected group of items.

To

generate a demand forecast, go to Master

planning > Forecasting > Demand forecasting > Generate statistical

baseline forecast.

The forecast bucket can be selected at forecast generation time.

The available values are: Day, Week, and Month.

The

number of buckets to generate a forecast for is set in the Forecast horizon field.

When the forecast strategy is set to Copy over historical demand, the end of

the historical horizon is ignored. The system copies the number of buckets

specified in the Forecast horizon field

to the forecast demand, starting from the date set in the From date field under Historical horizon. By copying

historical demand from a certain date forward, production planners can make the

plan for the next quarter in two ways:

·

By copying the demand from the same quarter last year.

·

By copying the demand from the previous quarter.

To

prevent confusion in the production plans, a certain number of forecast buckets

can be frozen. This number is set in the Freeze

time fence field.

On the Adjusted demand forecast page,

the cells for the frozen buckets are disabled, to give a visual indication that

those values should not be changed.

The

start date for the baseline demand forecast doesn’t have to be the current date

or a date in the future.

To set a different start date, use the Baseline forecast start date - From date field.

For example, in June, users can generate a forecast for the next year. Because

the forecast buckets between the end of historical demand and the start of the

baseline are missing, the predictions might not be accurate.

The Baseline forecast start date - From

date field has to be set to the beginning of a forecast bucket, for

example, in the United States, a Sunday if the forecasting bucket is the week.

The system automatically adjusts the Baseline forecast start date - From

date field to match the beginning of a forecast bucket.

The Baseline forecast start date - From

date field can be set to a date in in the past. In other words, it is

possible to generate a demand forecast in the past. This is useful, because it

lets users adjust the forecast service parameters so that the statistical

forecast generated in the past matches the actual historical demand. Users can

then continue using these parameter settings to generate a statistical baseline

forecast for the future.

Manual adjustments made in previous demand

forecasting iterations can be automatically applied to the new baseline

forecast if the Transfer manual adjustments to the demand forecast

check box is selected. If the check box is cleared, the manual adjustments are

not added to the baseline forecast – but they are not deleted. Manual

adjustments made to a forecast can be deleted only at forecast import time, by

clearing the Save the manual adjustments made to the baseline demand

forecast check box. Manual adjustments are saved at authorization

time. Therefore, if a user makes manual adjustments to the forecast, but

doesn’t authorize the forecast back to Supply Chain Management, the changes are

lost. For more information about manual adjustments and how they work,

A demand forecast generation can have a name and

comments to help users identify the forecast that has been generated. These

values are visible in forecast generation history on the Statistical

baseline forecast generation history page.

The intercompany planning group, item allocation

keys, and other filters can be applied at forecast generation time. These can

be used to improve performance or to split the data into manageable chunks.

However, note that a demand forecast is not generated for the members of any

item allocation key that is not associated with an intercompany planning group,

even if the item allocation key is selected in the query.